|

|

|

|

|

|

| The Hymark Performance ball bearing clutch

systems are the finest most durable and precise shifting driven clutch systems available!

We continually test and refine our products 12 months out of the year. This insures that

our customers get the very best products that money can buy. What we have found through years of testing in the snow and

running our dune buggies in the summer months in the sand is that in our near friction

free ball bearing clutch systems, the helix angle selection is not near as important as

the spring used. This is one reason that our spring selection is large and the reason for

the reduction of helix angles manufactured for this 1998 snowmobile season. Another reason

is that one can purchase five springs for the price of one helix and have greater

tune-ability.

Through continued refinement and testing

Hymark Performance has narrowed the helix selection to three basic helix angles, 45, 47.5

and 50 degree angles. We still have a large selection of helix angles available that are

in inventory. |

WE NOW HAVE TWO CLUTCH

SYSTEMS FOR THE YAMAHA REVERSE CAM CLUTCH |

1. BOLT-ON SYSTEM: This system is a completely bolt-on system. (There

is no machining required.)

The system includes a helix, helix carrier, Three bearing carrier assemblies, and a

spring.

This system is designed for 500cc snowmobiles and smaller. |

2. MACHINED SYSTEM:

This system requires you to send your secondary

sheave to us for machining.

The system includes a helix, cover plate assembly, and a spring.

This system is designed for high horsepower sleds, or race applications. |

HYMARK BALL

BEARING CLUTCH SYSTEM

(Bolt-on system) |

|

| Hymark Performance is now in the second

year of production of our bolt-on ball bearing driven clutch system for the new Yamaha

reverse cam clutch. Our bolt-on system for the Yamaha has under gone numerous

changes to refine this clutch system. We have changed the helix cover by adding a radius

between the towers to give added strength, this eliminated the cracking that could occur

with highly modified engines. We have also tapered the bushing hub area that positions the

inside of the spring. in order to eliminate spring binding, around the bushing hub. And we

have also been refining the bearing carrier, From the pin design to the material being

used. Continually trying to increase the roller clutch life on the higher horsepower

sleds. |

BALL BEARING

CARRIER

(Bolt-on system) |

| The Hymark Performance ball bearing

carriers for the Yamaha driven clutch are very unique in design. The bearing

carriers are made of 4140 chrome molly and are zinc plated to prevent rusting. Ball

bearings are installed in the bearing carriers by means of dowel pins. The bearing carrier

assembly installs in the machined locations of the stock clutch where the original clutch

buttons were located. Three bearing carrier assemblies are required per clutch.88-SMBOO374A: Bearing Carrier Assembly

88-D2220-20PS: Replacement Bearings |

YAMAHA

HELIX CARRIER

(Bolt-on system) |

| The Hymark Performance helix carrier is

machined from 6061 billet aluminum for precise balance and strength. This helix carrier

allows one to mount our hardened steel helix to the stock clutch with no machining

necessary. This Hymark helix carrier is red anodized to give the clutch a great looking

appearance. 88-SMB00376:

Helix Carrier |

MACHINED

ROLLER CLUTCH SYSTEM |

|

|

| Hymark Performance is now

producing a machined roller clutch system, for your high performance and race sled

applications. In this system you can use our original single ramp helix or our new double

ramp helix. The double ramp helix incapsulates the roller so that when you grab the brake

hard or come off a jump, the clutch never slams open and closed. This eliminates the

chance of the roller losing contact with the helix thus making the clutch even more

sensitive and faster reacting. With this system you will need to send the secondary sheave to us for machining.

We will machine the sheave so that you can bolt our hardened steel radiused helix to your

sheave. Then you merely install the spring, position the cover assembly over the three

bolt towers and tighten the nuts. With our new cover you now have even more spring

tune-ability, with the three original spring holes in the sheave and the five new holes in

the cover assembly. |

YAMAHA

COVER ASSEMBLY

(Machined system) |

| The Hymark Performance cover assembly is

machined from 6061 billet aluminum for precise balance and strength. The cover comes

complete with the bearings and bushing installed. This cover allows you to bolt our single

or double ramp helix onto your Yamaha machined sheave. The Hymark cover assembly is

black anodized, with silver lettering to give the clutch a rich looking appearance. 88-SMB00407: Cover Plate Assembly

Maching Yamaha Sheave |

YAMAHA

HARDENED STEEL RADIUSED HELIX |

| The Hymark Performance helix is a hardened

steel single point contact radius helix. A roller bearing clutch must have a radiused

surface for the roller bearing to contact. This will ensure center contact of the roller

bearing surface throughout a variety of helix angles. Hymark Performance has developed a

series of helix profiles with our patented radiused contact surface. These helix are

machined from high quality steel and heat-treated to near bearing hardness. Even though

the radiused helix is made of high quality steel, the special design adds only ounces to

the driven clutch. These helix are designed to last a lifetime. 88-A/C45: Helix

88-A/C47.5: Helix

88-A/C50 : Helix

88-AC/YAM45 : Double Helix

88-AC/YAM47.5: Double Helix

88-AC/YAM50 : Double Helix

NOTE: Other

helix angles available upon request. |

YAMAHA

HELIX APPLICATION CHART |

| 88-AC/YAM50 Degree Helix |

0 TO 4000 ft. elevation |

| 88-AC/YAM47.5 Degree Helix |

4000 TO 8000 ft. elevation |

| 88-AC/YAM45 Degree Helix |

8000 TO 12000 ft. elevation |

| NOTE: Three bearing carriers, one helix carrier,one

helix, one shim pack and one spring are required per clutch. |

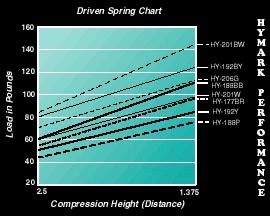

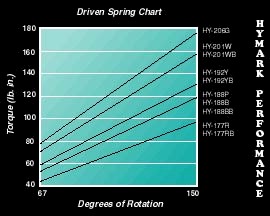

HYMARK

DRIVEN CLUTCH SPRINGS |

|

| Hymark Performance has

developed several new springs for our ball bearing clutch systems. We have also developed

spring torque charts and spring compression charts in order for one to more fully

understand which spring or springs would be desired. In most of the new Yamaha

driven clutches, we would recommend the use of our 88-HY201W spring or the 88-HY192Y

spring. 88-HY188P: Spring .188" wire diameter

88-HY192Y: Spring .192"

wire diameter

88-HY201W: Spring .201"

wire diameter

88-HY206G: Spring .206" wire

diameter |

|

|

|

| |

|

|

|

|

|